Reliable Moisture & Gas Removal for Mercury Monitoring

Overview

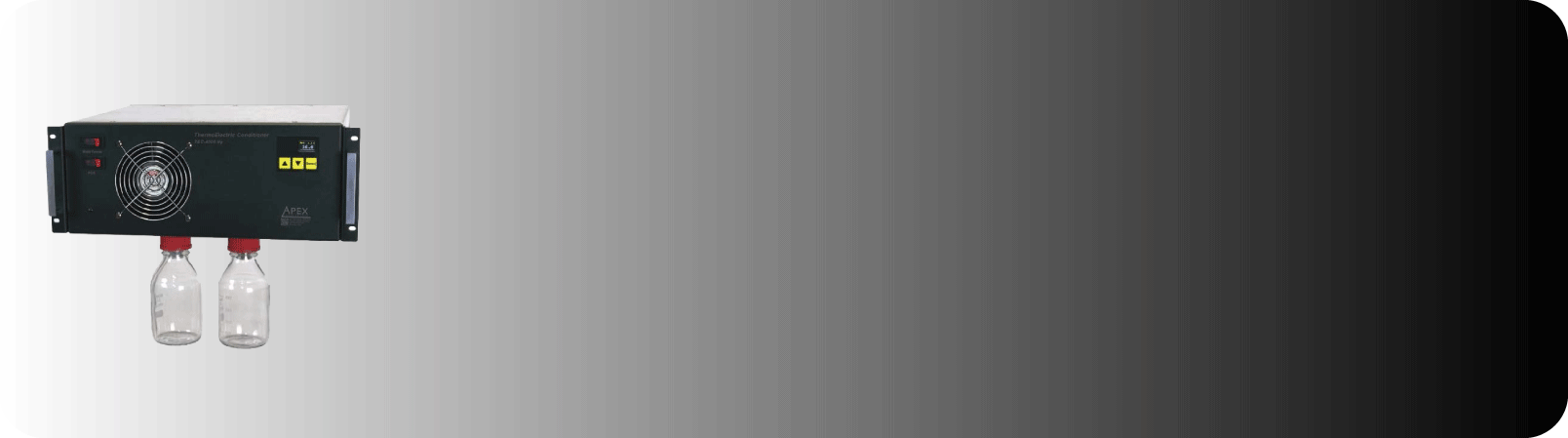

The TEC-4000Hg Thermoelectric Gas Conditioner is designed for effective moisture and gas removal, optimised for use with the XC-6000 Sorbent Trap Mercury Monitoring System (PS-12B).

Mounted in a 19-inch cabinet, this robust, closed, dual-channel gas conditioning system efficiently collects condensate in sample bottles while delivering dry, acid-free gas to the meter console.

Key Features & Benefits

✔️ Extremely reliable solid-state heat pump for long-term operation

✔️ Durable heat pump system, designed to withstand harsh industrial environments

✔️ Low-resistance heat exchanger with high thermal conductivity for maximum efficiency

✔️ Hastelloy condensers for superior corrosion resistance

✔️ Integrated PID temperature controller for precise thermal regulation

✔️ High-efficiency heat exchanger with copper base & U-tube heat pipes for optimal cooling

✔️ Compact & rack-mountable design for seamless integration with the XC-6000 system

Technical Specifications

- Refrigeration: 50-watt solid-state thermoelectric heat pump

- Temperature Display: OLED display, ±0.1 ºC/ºF accuracy

- Temperature Control: Variable DC with PID control (3-button keypad)

- Cooling Capacity: 100 BTU/hr

- Cold Block: Insulated aluminium

- Condensers: Reverse-flow C276 alloy condensate separator (1″ × 7″, 4″ active cooling zone)

- Condensate Removal: Gravity bottle, 10 mL/min flow rate

- Heat Exchanger: Low-profile heatsink with six 6-mm U-tube heat pipes, coated fins for corrosion resistance, 120-mm axial fan

- Rated Flow Rate: 2 LPM per channel at 30% moisture

- Ambient Operating Temperature: 32°F to 104°F (0°C to 40°C)

- Auxiliary Temperature Controller: Digital controller for heated jumper, Type-K thermocouple input

- Power Supply: 120V AC (60Hz, 15A max) or 240V AC (50Hz, 10A max), IEC C-13 inlet

- Dimensions: 17″ W × 7″ H × 17″ D (43.2 cm × 27.8 cm × 43.2 cm)

- Weight: 22 lbs (10 kg)

Reliable, Efficient, and Built to Last

The TEC-4000Hg Gas Conditioner provides high-efficiency gas drying for mercury monitoring applications, ensuring accurate sample analysis and system longevity.